You can almost find EVA foam material everywhere!

They are usually provided by EVA foam suppliers as EVA foam sheets, EVA foam rolls, EVA foam puzzle mats, EVA foam tapes and so on. But do you really know this foam material? Here we are showing you the way to know EVA foam materials better.

Just simply follow us as below! You will get to know what the EVA foam is, how this foam material is manufactured and fabricated by foam manufacturers. This can definitely guide you when you want to buy EVA foam sheets.

Definition of EVA foam material

EVA (Ethylene-vinyl acetate) foam is made from blended copolymers of ethylene and vinyl acetate. In one sheet of EVA foam, The weight percentage of vinyl acetate usually ranges from 10 to 40%. Polyethylene material is another important element for EVA foaming production. The variation amount of foaming additives and catalysts in the molding process of EVA foam can affect its density, hardness, color, resilience and so on.

EVA foam materials are of closed cell foam structure. They have lots of excellent performances including good water & moisture resistance, excellent cushioning & shock absorption, strong heat insulation and long term durability etc.. They are quite frequently used by various industries so that we can find out it in many places and products, such as shoe insole, soft foam mats, foam packaging, yoga block, swimming kickboard, floor underlay, custom EVA foam components and so on.

Look: Here is how EVA foam sheets are manufactured

After the below 4 production processes, we will see a full sheet of EVA foam materials. You could also take a look at this video about EVA foam manufacture process.

* Formula Preparation for Plastic Raw Materials of EVA foam Having a precise chemical formula beforehand can make a good beginning for producing the right quality of EVA foam. At first, our technicians need to work very carefully on the proportion of every plastic raw materials and catalysts that will be blended together.

Having a precise chemical formula beforehand can make a good beginning for producing the right quality of EVA foam. At first, our technicians need to work very carefully on the proportion of every plastic raw materials and catalysts that will be blended together.

The main materials includes plastic particles of Ethylene Vinyl Acetate Copolymer and Polyethylene, filler of calcium carbonate and talcum powder, foaming agent of AC, DCP crosslinking agent, Foaming promoter of zinc oxide, lubricating agent of stearic acid.

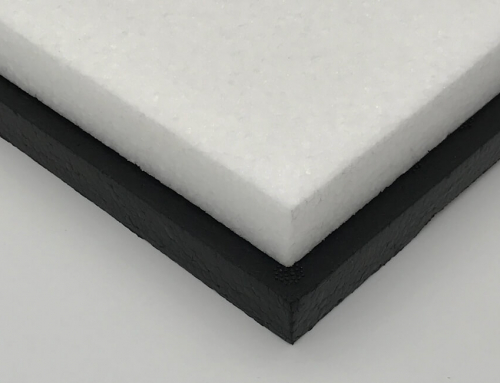

Beside those above-mentioned main elements, in order to featuring our EVA foam materials, some essential adjuvants are utilized to make it. Black and white color are the typical color for EVA foam. To produce various color EVA foam, color masterbatch is widely used in production to colorfully feature EVA foam materials. Also to enhance the heat and fire insulation of EVA foam sheet, we add the fire retardant additives into the chemical formula. Moreover, for anti-static EVA foam packaging of precious electronic devices, we can use anti-static agent to manufacture the anti-static EVA foam materials.

After all the chemical raw materials well checked and ready, we can go for the next process.

* Banbury Mixer Processing

Once we have the right proportion of plastic raw materials and additives, our production operator will put them into our Banbury mixer machinery. The internal mixer has a fully and well-sealed container which has sufficient capacity to keep large amount of production raw material. It also works highly efficient and is very helpful for mass production of large volume.

In this process, the previously prepared material will be chemically blended by heating and pressure inside the Banbury mixer. For actual operation , our technicians will need to set up the right heating temperature and pressure of internal mixer. After a certain period of time our operator set up before, the processing of the raw materials can be completed.

In below picture, you can see what the semi-finished product looks like after the first working flow. The EVA raw materials are blended with other plastic materials and catalysts. They are solid materials originally and now turns to be pasted and sticky like mashed potato under effect of heat and high pressure.

* EVA Material Sheet Processed by Extruder and Conveyor

When having the mashed plastic blend at hand, our factory operator will handle it into our exturder. Before starting up the sheet extruder, our technicians need to adjust a suitable working speed of the machine. Also they will work carefully to make sure the extruded EVA foam sheets are of the desired thickness that will be used for foaming process.

After put inside the exturder, the mashed plastic blend will be squeezed by high pressure generated by the machine. The important part of this process is the mashed bend will go through metal rollers that will make them turn to be flat sheets. The big metal rollers of conveyor has been set up at a appropriate working speed before everything starting. The EVA sheets we will get after this process is not foamed material. They are high density plastic sheets in nature and are ready for the last also most important part – foaming process.

* Foaming Process by EVA Mold Foaming Vulcanizing Machine

Our foaming machinery works like a toaster. Our technicians will adjust the foaming machine to a right working temperature and pressure. Different temperature can affect the density, resilience and quality of EVA foam sheet. In this process, we will utilize the above mentioned high density EVA sheets to finish the whole process. Our factory operator will gather some pieces of those sheets and put them neatly in piles. Then the piles of EVA sheets will be placed well into the foaming mold which made by high quality stainless steel and can resist high temperature and pressure. Besides, as the EVA foam materials are formed in mold, the mold size apparently determine the size of EVA foam sheets. Usually the thick EVA foam sheet is of 2 m in length and 1 m in width. For long EVA roll, we have special machine to fabricate it and can make them longer and wider.

Inside the foaming mold, the EVA sheets blended with catalysts will actually undergo a vulcanization process. After a period time of heating by high temperature, they will finally be foamed and become the EVA foam sheets with wanted colors and density etc.. The just finished EVA foam materials are thick sheets, but they are quite flexible and handy to be fabricated to any thicknesses, shapes, rolls and so on. We will introduce you some regular fabrication for EVA foam sheets below.

Take a quick look at EVA foam sheet specification

Size: Around 2 m in length, 1 m in width and 0.5 mm to 100 mm of thickness. It actually depends on the size of foaming molds foam manufacturers possess. (The maximum width of EVA foam roll can reach to 2 m and maximum length can be 100 m or more. )

Color: Black and white are typical color; Blue, red, green, yellow EVA foam are also available.

Density: 33 kg/m³ to 280 kg/m³

Hardness: 15 degree to 80 degree Shore C; 40 degree of EVA foam is the most widely used model.

Note: EVA foam materials have also been categorized and differentiated depending on its resilience, hardness, surface and foaming cell structure.

For more detail, you could contact us or ask for help of our technical sales at info@www.foamtechchina.com.

What is the advantages of EVA foam material on properties

As EVA foam materials has many excellent advantages and performances for actual applications, they has become one of the most popular foam materials. Here we will illustrate some benefits it brings.

Cushioning

EVA foam materials are foamed plastic and rubber blend, not solid and hard plastic and rubber material. Generally for low density and mid-density EVA foam materials, they can be naturally elastic and flexible. And they are also tougher than soft polyurethane foam. As they have good cushioning capability with economical cost, so people frequently use it as cushioning materials. You could find them in lots of products including knee pads, EVA foam mats, foam packaging and inserts, even golf putting green that people use the large EVA foam sheet as cushion underground.

Resilience

As mentioned before, when producing the EVA foam sheet, we can put elements of natural rubber and other resilient additives. This way we can formulate a highly resilient EVA foam materials once we utilize those resilient elements. Sometimes customer requires the high resilient EVA foam and it is actually the blend of EVA and rubber foam. A highly elastic EVA foam materials can be widely used to enhance the cushioning and durability of products. Some foam products you may see the highly resilient EVA foam materials such as squeegee blades, foam seals, foam gaskets, seat cushions and so on.

Insulation

EVA foam is a closed cell foam material. They are naturally good at insulation. Also other closed cell foam materials do have better insulation abilities than open cell foam. For production, EVA foam materials need to go through vulcanization procedure where they are formed with a cross-linked also closed cell molecular structures. The insulation abilities of EVA foam includes heat and thermal insulation.The can resist temperature from minus 30 degree centigrade to 80 degree centigrade. Besides, we can also put ire retardant additives and anti -static agents to enrich the insulation performance of EVA foam materials.

Resistance

Resistance ability of EVA foam materials is similar to its insulation. But here when we talk about its resistance ability, it refers to resistance to solvent and noise. Due to its closed cell foam structure, EVA foam materials in different densities or hardness can all have excellent resistance to water, moisture, oil and sound. The closed cell structure can make the foam have a smooth and flat surface that can help raise its resistance. In some products like flooring underlay, as you can see, EVA foam performs excellent resistance.

Buoyancy

EVA materials is widely used for marine products and applications. EVA foam has strong buoyancy in closed cell structure. They are excellent at water resistance. Also you should know the low density and mid density EVA foam materials are lightweight and portable. These advantages make them quite suitable and outstanding for marine products. You can easily see EVA foam materials for water floats, boat cushion mats, swim kickboards and even as foam parts in life jackets.

Durability

Plastic materials are naturally good for long term usage. EVA foam can be added natural rubber and EPDM material which can not only improve its resilience, but also enhance its durability and make it undergo a long term usage. Rubber materials are durable but they are so heavy that sometimes they are not handy and portable to use. Compared with rubber materials, EVA foam are much portable and easy to move around. After adding resilient additive for its production, EVA foam can actually performs better than rubber materials, also deliver a long term durability.

How we fabricate EVA foam material

People usually do not need the large and thick EVA foam sheets, so we have more foam fabrication capabilities to custom tailor those foam sheets. Below we are introducing you some popular and effective fabrication methods for EVA foam materials.

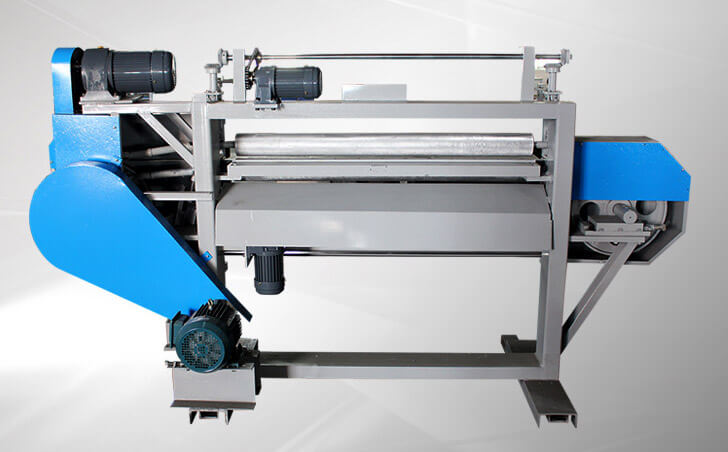

Foam Skiving

As you may know, the original EVA foam sheets coming out from the foaming machinery have thickness up to 100 mm. They are so thick that customers usually ask us to provide them thinner foam sheets. Besides, foam skiving is always be the first step for the rest foam fabrication processes. In order to make this, we have equipped with professional foam skiver which can be used to split the EVA foam sheets to any desired thickness. Also the machine can be used to skive other foam sheets such as Polyethylene foam sheet, Polyurethane foam sheet, foam rubber sheet and so on. Our technicians need to first adjust our foam skiver, and they will put the large foam sheets through the sharp blades. Then we will soon have the EVA foam sheets or blocks of your wanted thickness with tight tolerance.

Foam Sawing The sawing process is mainly used by us to cut custom foam sheets, blocks and strips. It is a very handy and efficient way to fabricate the EVA foam materials. After having EVA foam sheets of wanted thickness through skiving, our factory staff will manipulate the foam sawing machine to cut the foam sheets to desired length and width. The sawing methods are refer to 2 ways, one is vertical sawing and the other is horizontal sawing. Our factory utilize the vertical sawing most. Our staff will place foam sheets onto the platform of sawing machine. They will check carefully of the size they want and adjust the machine. Then they will start up the foam sawing machine and just put the foam sheets or blocks through the cutting blade at high speed operation. We will finally get customer the wanted size of foam sheets, blocks and strips in a quick time.

The sawing process is mainly used by us to cut custom foam sheets, blocks and strips. It is a very handy and efficient way to fabricate the EVA foam materials. After having EVA foam sheets of wanted thickness through skiving, our factory staff will manipulate the foam sawing machine to cut the foam sheets to desired length and width. The sawing methods are refer to 2 ways, one is vertical sawing and the other is horizontal sawing. Our factory utilize the vertical sawing most. Our staff will place foam sheets onto the platform of sawing machine. They will check carefully of the size they want and adjust the machine. Then they will start up the foam sawing machine and just put the foam sheets or blocks through the cutting blade at high speed operation. We will finally get customer the wanted size of foam sheets, blocks and strips in a quick time.

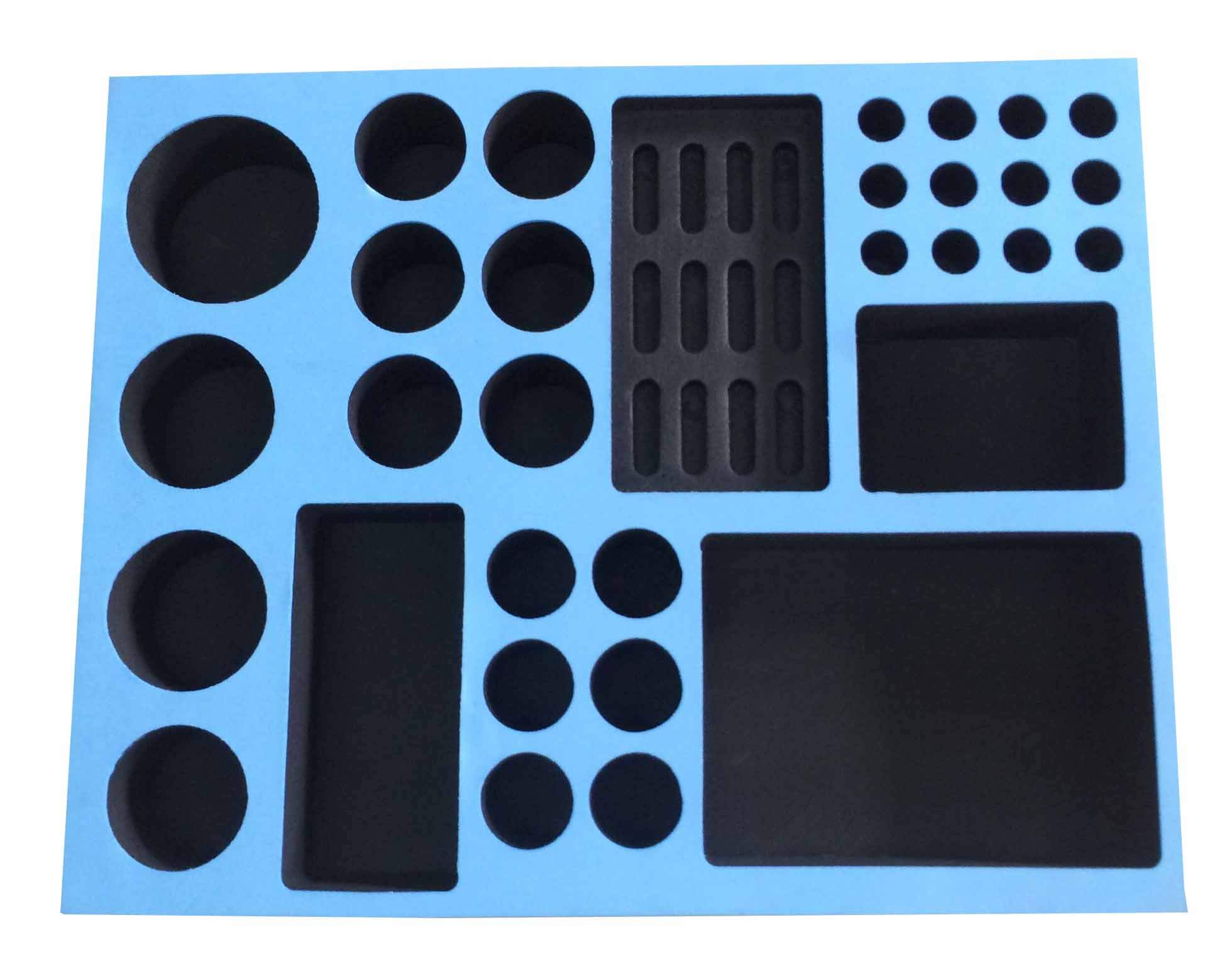

Custom Die-cutting

You can see die cutting are used in many industries like paper packaging where people use the steel made die for cutting out paper box. We use the die cutting the same way for foam fabrication. To fabricate custom foam parts, die cutting is frequently used for EVA foam packaging, foam case inserts, foam profiles, foam gaskets and pads. The most important parts for using foam die-cutting is we need to decide the correct CAD drawings for custom foam parts. Then we will develop the steel die-cutting mold according the computerized product drawing. Once the die cutting mold ready, we will use EVA foam sheet with mold to working in die cutting machinery. They will help us generate the custom foam parts correctly and quickly. For some complicated EVA foam packaging, we may also use adhesive lamination to have two or more foam parts laminated together. This way they can function as a whole part.

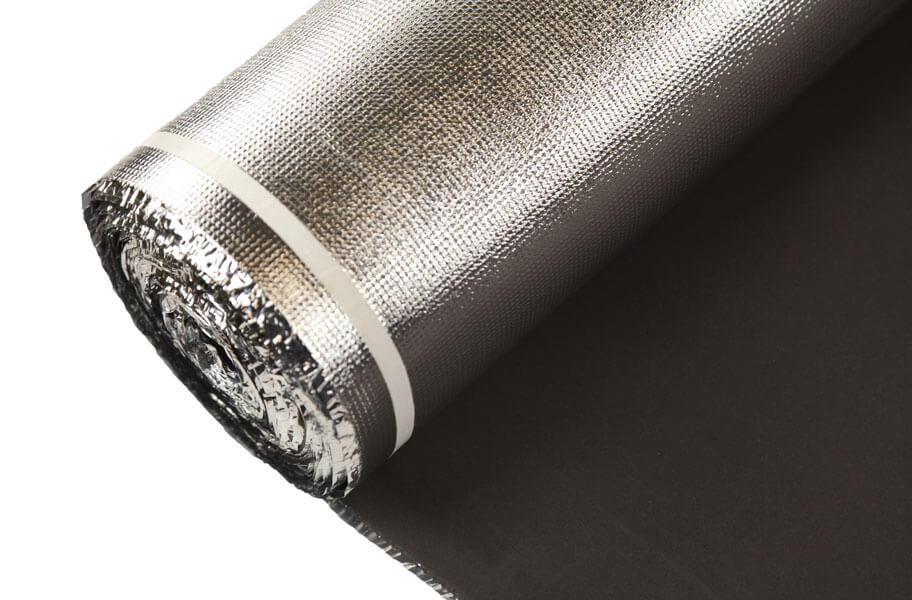

Foam Lamination

Foam lamination is needed when customers want EVA foam materials have sticky adhesive backing, felt surface, fabric and film backing or when custom foam fabrication needs foam lamination to facilitate. Our foam lamination capabilities are key to make the EVA foam composites for customers’ project. Lamination methods can be categorized in two main ways, the first PAS lamination also adhesive lamination and the other heat lamination. The first one needs adhesive materials like hot melt adhesive or acrylic adhesive and release liner backing. The other mainly works with hot heating machine where heated foam surfaces can be sticky and laminate together. EVA foam Products like EVA foam tapes, EVA adhesive pad and foam floor underlay with silver foil or film are all using lamination to achieve.

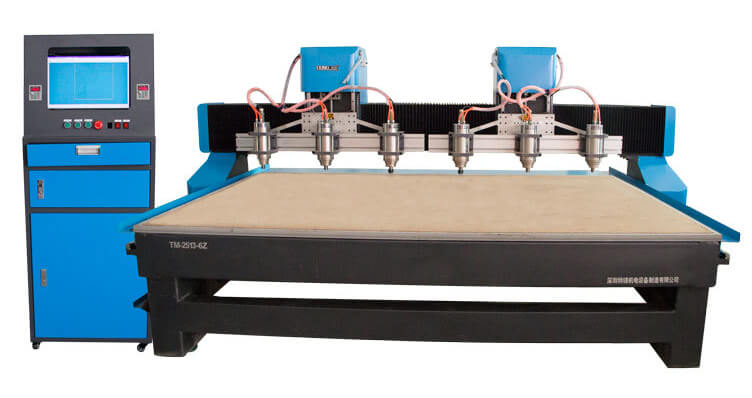

CNC contouring cut For complicated foam packaging, such as tool control cases with different thickness cutout shapes inside, we suggest to use CNC contouring engraver to make it. CNC contouring cut can work well for custom foam cut with different cutout thickness. It is a precise and efficient way to use. Before using this method, computerized drawings for foam parts need to be confirmed. Besides the drawings for CNC contour cutting are usually 3D version files. Our technicians will set up the CNC cutting machine with the right statistics compatible with the 3D foam part drawing. Also the machine can be used to cut thickness of around 8 mm EVA foam materials. The CNC contouring cutting is frequently used to fabricate EVA protective foam inserts also Polyethylene foam packaging.

For complicated foam packaging, such as tool control cases with different thickness cutout shapes inside, we suggest to use CNC contouring engraver to make it. CNC contouring cut can work well for custom foam cut with different cutout thickness. It is a precise and efficient way to use. Before using this method, computerized drawings for foam parts need to be confirmed. Besides the drawings for CNC contour cutting are usually 3D version files. Our technicians will set up the CNC cutting machine with the right statistics compatible with the 3D foam part drawing. Also the machine can be used to cut thickness of around 8 mm EVA foam materials. The CNC contouring cutting is frequently used to fabricate EVA protective foam inserts also Polyethylene foam packaging.

Foam Thermoforming

When people wants EVA foam materials to be both more resilient and durable, foam thermoforming can be a good way to go. This technique can also make 3D custom foam parts. Take look at foam knee pad and knee pad inserts so you will know the benefits foam thermoforming can bring. For utilize this fabrication method, custom mold of foam parts need to be developed according to product CAD drawing. Then we will use our EVA foam materials and the developed mold working with our thermoforming machinery. Thermoforming as you may see literally is related to heating and temperature. Our technicians will work carefully to adjust the termoform machines with appropriate heat temperature and pressure. The custom EVA foam parts will be formed in the mold under heating and pressure. Most of 3D foam parts are using foam thermoforming technique to achieve including boat seat cushion and other custom foam parts.

EVA foam applications and products

Utilizing EVA foam materials of different colors and densities also with various foam fabrication techniques, we can make much more foam products than you would imagine. Last we are showing you some of the EVA foam products.

EVA Shoes Insole

EVA foam materials are one of the most popular material as shoe insole. The EVA foam used for shoe industry takes up to 60% of all amount of EVA foam. The EVA insole are mainly manufactured by injection foam molding method. This technique is different from the molded foaming method we introduced in the beginning of this article. You could take a look at SoleTech EVA shoe soles material for more information.

EVA Toy

As EVA foam materials are available in various colors, it is easy to be eye-catching and attractive for children. They can also be easily fabricated to any custom sizes and shapes. EVA toys and crafts includes EVA building blocks, EVA swords, EVA masks, foam craft sheets and so on.

EVA Foam Packaging EVA foam materials are ideal for fabricating foam packaging. They are naturally cushioning and resilient material. They can also be flexibly fabricated by many machines and techniques like die-cutting and CNC contouring cut. You can always find them in products packaging and case inserts.

EVA foam materials are ideal for fabricating foam packaging. They are naturally cushioning and resilient material. They can also be flexibly fabricated by many machines and techniques like die-cutting and CNC contouring cut. You can always find them in products packaging and case inserts.

Swimming Kickboard

As above mentioned EVA foam has good buoyancy and they has excellent floating ability underwater. On the other hand, the EVA foam materials can be made in low density with lightweight property. Therefore they are quite suitable for marine market usage. Swimming kickboard is one of products made by EVA foam materials.

Foam Puzzle Mats

EVA foam puzzle mats are made of molded EVA foam materials usually with anti-slip texture finishing on surface. They are quite popular to use in many occasions such as home flooring, basement flooring, home gym and martial arts studios etc.. People like to use them because they are quite easy to install with interlocking tabs. Also foam puzzle tiles can provide good cushioning comfort for flooring.

EVA Foam Roller and Block

EVA foam material is frequently used to develop products for sports applications. The EVA foam rollers and blocks are currently popular yoga products. Foam rollers can be fabricated by both thermoforming and injection molding methods. On the other hand, EVA foam blocks are manufactured by custom foam sawing. They are also available in a lot of colors for customer to choose. Also here is the detailed guide for how to correctly use foam roller.

EVA foam material is frequently used to develop products for sports applications. The EVA foam rollers and blocks are currently popular yoga products. Foam rollers can be fabricated by both thermoforming and injection molding methods. On the other hand, EVA foam blocks are manufactured by custom foam sawing. They are also available in a lot of colors for customer to choose. Also here is the detailed guide for how to correctly use foam roller.

Having a precise chemical formula beforehand can make a good beginning for producing the right quality of EVA foam. At first, our technicians need to work very carefully on the proportion of every plastic raw materials and catalysts that will be blended together.

Having a precise chemical formula beforehand can make a good beginning for producing the right quality of EVA foam. At first, our technicians need to work very carefully on the proportion of every plastic raw materials and catalysts that will be blended together. The sawing process is mainly used by us to cut custom foam sheets, blocks and strips. It is a very handy and efficient way to fabricate the EVA foam materials. After having EVA foam sheets of wanted thickness through skiving, our factory staff will manipulate the

The sawing process is mainly used by us to cut custom foam sheets, blocks and strips. It is a very handy and efficient way to fabricate the EVA foam materials. After having EVA foam sheets of wanted thickness through skiving, our factory staff will manipulate the

For complicated foam packaging, such as tool control cases with different thickness cutout shapes inside, we suggest to use

For complicated foam packaging, such as tool control cases with different thickness cutout shapes inside, we suggest to use  EVA foam materials are ideal for fabricating foam packaging. They are naturally cushioning and resilient material. They can also be flexibly fabricated by many machines and techniques like die-cutting and CNC contouring cut. You can always find them in products packaging and case inserts.

EVA foam materials are ideal for fabricating foam packaging. They are naturally cushioning and resilient material. They can also be flexibly fabricated by many machines and techniques like die-cutting and CNC contouring cut. You can always find them in products packaging and case inserts.

EVA foam material is frequently used to develop products for sports applications. The EVA foam rollers and blocks are currently popular yoga products. Foam rollers can be fabricated by both thermoforming and injection molding methods. On the other hand, EVA foam blocks are manufactured by custom foam sawing. They are also available in a lot of colors for customer to choose. Also here is the detailed guide for

EVA foam material is frequently used to develop products for sports applications. The EVA foam rollers and blocks are currently popular yoga products. Foam rollers can be fabricated by both thermoforming and injection molding methods. On the other hand, EVA foam blocks are manufactured by custom foam sawing. They are also available in a lot of colors for customer to choose. Also here is the detailed guide for

By using foam lamination and slitting capabilities, EVA foam materials can be fabricated as foam tapes with or without adhesive back. They can be used for lots of places where sealing and cushioning are needed. They are also low cost substitute for foam rubber tapes like Neoprene, PVC Nitrile blend and so on.

By using foam lamination and slitting capabilities, EVA foam materials can be fabricated as foam tapes with or without adhesive back. They can be used for lots of places where sealing and cushioning are needed. They are also low cost substitute for foam rubber tapes like Neoprene, PVC Nitrile blend and so on. By exploiting foam fabrication capabilities especially foam thermoforming and lamination, EVA foam material can be processed as many 3D foam parts and components. They will provide better cushioning and shock absorption for applications they serve. Also foam lamination technique can make the EVA foam parts working well with fabric, film and adhesive backing.

By exploiting foam fabrication capabilities especially foam thermoforming and lamination, EVA foam material can be processed as many 3D foam parts and components. They will provide better cushioning and shock absorption for applications they serve. Also foam lamination technique can make the EVA foam parts working well with fabric, film and adhesive backing.

Very nice!

Hi Sir,

Thanks for your kind comments! We will keep up on releasing more informative knowledge of foam products.

Hi, Thanks for sharing such useful information about EVA foam. Keep on working!

Hi Taylor, Thanks for your kind comments!