Foam material are available in closed cell and open cell structure, and they are also available in a broad range of densities and firmness, which can help foam perform well on shock absorption, sound dampening, water resistance, and heat insulation. With all versatile properties, foam products are naturally suitable for using in many construction applications such as filtering, gasketing, cushioning and insulation etc..

Here below to check out some most popular foam products used in construction applications.

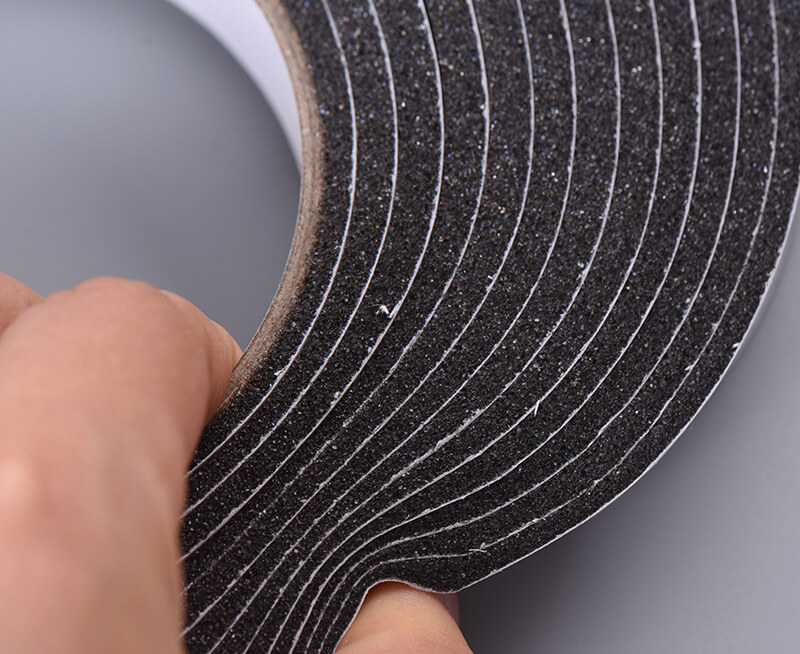

Construction Foam Tapes

When most people think of foam tapes, they think of the foam used to keep the insulation in place. However, foam tapes have a wide variety of applications in many industries. In the construction industry, foam tapes are often used instead of mechanical fasteners, and they’re used because foam tapes have several advantages over traditional fastening methods. This article will discuss the different types of foam tapes and their applications in the construction industry.

What kind of foam tapes are used in construction applications?

Foam tapes are an essential part of many construction applications. They seal gaps and joints, providing a weather-tight seal that helps prevent air and water infiltration. Foam tapes come in various widths and thicknesses, and they can be used in interior and exterior applications.

Some of the most common types of foam tapes used in construction are closed-cell foam tapes, open-cell foam tapes, and self-adhesive foam tapes. Each foam tape has its advantages and disadvantages, so it’s important to choose the right type of tape for the job.

The most common foam material used for making foam tapes includes closed cell foam such as EVA foam, crosslinked Polyethylene foam, PVC foam, EPDM foam and Neoprene foam etc.. Also open cell foam such as Nitrile foam rubber, Polyurethane foam, open-cell EPDM foam and so on.

Closed-cell foam tapes are the most durable type of tape and are also the most effective at preventing air and water infiltration. However, they’re also the most expensive type of tape. Open-cell foam tapes are less durable than closed-cell foam tapes, but they’re more flexible and easier to work with.

Self-adhesive foam tapes are the most accessible type of tape, but they don’t provide as tight of a seal as other types of foam tape. When choosing a foam tape for a construction application, it’s essential to consider the project’s specific needs.

Foam tapes are an important part of many construction applications, so choosing the right type of tape for the job is important.

What advantages of foam tapes for construction industries?

Foam tapes have a variety of advantages in construction applications. They are versatile and can be used on various surfaces, including wood, metal, glass and plastic. Foam tapes are also durable and resistant to weathering and water, which makes them ideal for use in outdoor applications.

In addition, foam tapes are easy to install and remove and support gravity-fed and adhesive-backed systems. As a result, foam tapes offer many benefits for construction applications.

When selecting foam tapes for a particular project, it is important to consider the job’s specific needs. For example, some foam tapes are designed for high-temperature environments, while others are better suited for low-temperature applications.

By selecting the type of foam tape best suited for the job, construction professionals can ensure that the project will be completed successfully.

If you are in the construction industry, it is important to know the different types of foam tapes available. Each type of tape has advantages and disadvantages that should be considered when making a purchase decision.

Foam Closure Strips for Roof Panels

In simple words, roofing panel foam closure strips serve as the premium sealing for the metal roofing. They also work as the ‘premium cushion seals’ for the polycarbonate roofing panels. The foam closure strips enhance the roof’s overall performance by restoring the quality of the metal for years to come. The dense foam rubber strips are used on either side of the metal panels. These foam closure strips are water-resistant, cushioned, and durable material for added coverage. It helps seal the gap of the roofing panels seamlessly and averts the entry of animals and insects inside the home.

Typical sponge that are used for making custom foam closure strips consisit of closed cell Polyethylene foam, EVA foam and open cell Polyurethane foam. They are made via foam fabrication methods such as die-cutting or CNC contour cutting.

How do these foam closure strips work?

If you are considering longevity for your roof, getting the roofing panel foam closure strips is a good investment. It will help to maintain the roof for a long time, and you can save it from all sorts of weather conditions. Here’s how the foam closure strips work:

When foam closure strips are installed, they fill up the space between the base of the roof and the highest portion of the metal panel.

When installed on your metal roofing, these strips work as an insulator against the noise and winds.

A few companies provide customized foam closure strips to fit the metal roofing profile of any size. They are best for commercial and residential purposes and corrugated roofing structures too.

The regular size of these strips is 36 inches, with a width somewhere around one to two inches and a thickness of about one inch. The EVA foam is used to make the strips that fit properly to your metal roofing.

Get the closure strips today if you do not want any long-term damage to your roof. It will safeguard the metal panels.

Benefits of roofing panel foam closure strips

No More Leakages: These closure strips are made from high-quality EVA foam that helps with moisture resistance. It helps safeguard your home from rain, snow, and sleet. There will be no more natural disturbances caused.

Works as an Insulation Cover: If you are irritated and frustrated with the surrounding noise, these foam closure strips work as an excellent insulation cover. After installation, they block the unnecessary sound from outside or due to rain and storm.

Tight Sealing of the Roof: The foam closure strips work as the tight sealing for the roof. You will notice no water leakage and an extra layer of protection to your home.

Withstands the Long-Term Abrasions: The best part of getting the roofing panel foam closure strips is that they are made of EVA foam that provides good cushioning and seals the metal roofing properly. They are lightweight, and the foams can withstand any form of long-standing abrasions.

Reduces the Amount of Light: If the metal roofing does not have foam closure strips, it will let sharp sunlight during the summers. To protect your property from the sunlight during the peak summer season, you can install foam closure strips to fill that gap. It will drastically reduce the light peeking in through the metal roofing.

The roofing panel foam closure strips are an excellent investment because it helps safeguard your home or commercial places from weather, water, and extreme moisture. Even it avoids letting off the pests or animals inside. So, it is a good investment for maintaining your metal roof for a long time.

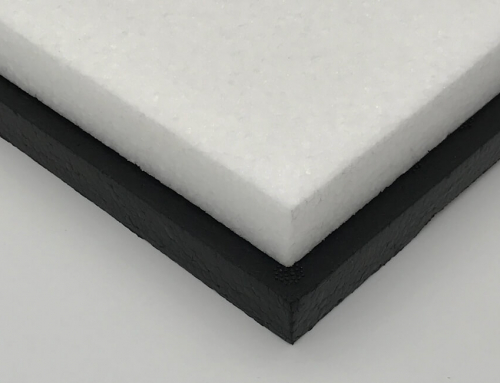

Foam Flooring Underlayment

As you consider your next household project, what comes to mind? It’s easy to notice walls, but what about the floors? Our floors undergo a remarkable amount of wear and tear, and having a good, professional layout underfoot can keep you comfortable, add value to your home, and even save on energy costs.

Most of foam floor underlayments are made of closed cell foam materials such as cross-linked Polyethylene foam, Non-crosslinked Polyethylene foam, EVA foam and so on. Besides foam, fiber, felt and rubber can also be used for making floor underlayment.

Foam flooring underlayment is one such great option. Let’s take a look at the technology to better understand what is does, and how it can work for you.

What is foam flooring underlayment?

Underlayment is simply a layer of padding between your subfloor (which may be made of concrete, wood, brick, or of another substance), and your new floor. Underlayment adds a layer of softness and comfort underfoot, can help keep you a bit warmer, and can help protect your new floor over its lifetime.

Foam flooring underlayment is simply underlayment made of inexpensive and easy to install foam sheeting. This is the most basic, economical, and widely used form of underlayment available. It comes in a variety of styles, and some even feature adhesive backing, making installation even simpler.

How does foam flooring underlayment work?

Foam flooring underlayment attaches to your subfloor, providing a layer of cushioning and protection underneath your new flooring material. Simply spread it out over your subfloor, and make sure it’s firmly in place. Make sure that you carefully cut and fit the foam flooring underlayment to match the dimensions and perimeter of your room.

Next, on top of the secured foam flooring underlayment, install your new flooring. Wood and laminate are two of the easiest materials to use with foam flooring underlayment, but some types of vinyl can work well, too.

What are the benefits of foam flooring underlayment?

The benefits of installing foam flooring underlayment are numerous, from heat retention, to added comfort when walking on the new floor, to a longer life for your newly installed floor.

Every item benefits from some cushioning and cradling and this is exactly when flooring underlayment accomplishes. Instead of forcing your new flooring to be ground underfoot into a rough layer of concrete or wood, the underlayment serves as a soft layer of protection, and makes your new floor quieter and more comfortable to walk on, and protects it from unnecessary wear and tear.

The added layer of protection can also help your home retain head a little bit better, and keep your floors slightly warmer in the cold. This is because, just as with layers of clothing, the underlayment can trap some heat and help your home lose less warmth through an unprotected floor. This will keep your family more comfortable, and make your new floor easier to walk on.

Some foam flooring underlayment can also come with vapor barrier technology, allowing you to use it safely in damp or humid areas, such as basements. This will help protect your new floor from moisture damage, and avoid the buckling or discoloration that can accompany water damage. The minimal investment of foam flooring underlayment can add years to your new laminate or hardwood flooring, and is a simple and economical step worth taking as you renovate your home.

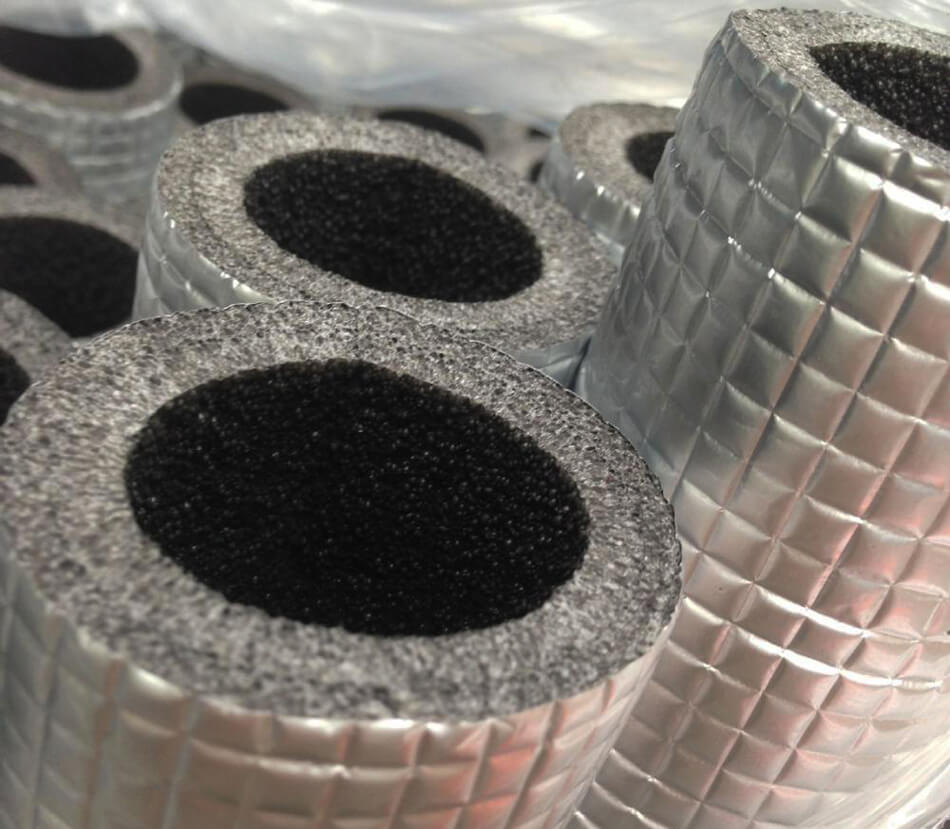

Foam Pipe Insulation

Foam pipe insulation consists of insulating tubes, typically made from closed-cell polyethylene foam (in short, “PE”) or PVC Nitrile foam rubber (NBR foam). The purpose of these tubes is to cover pipes to provide additional protection and insulation. This material is highly sought-after in waterproofing applications, so it is a perfect match for the needs of pipe insulation overall.

Keep reading to learn more about foam pipe insulation and its many benefits.

How does foam pipe insulation works?

Cold pipes can produce excessive condensation without any insulation when they encounter humidity and hot air. The condensation from the temperature contrast can produce a wide variety of issues, including harmful mold and rot. In extreme cases, a lack of pipe insulation can also cause extensive water damage in the long run.

Thankfully, foam pipe insulation is a quick, cheap, and effective way to prevent “pipe sweating” and condensation. The foam tubes slip over the pipes, acting as a barrier between the temperature of the pipe and external humidity and weathering. Insulating foam is incredibly durable but also lightweight and flexible. This means that it will not strain the pipe, and there is no risk of damaging anything in the pipe network. Because the tubes are made from polyethylene foam or Vinyl Nitrile foam, they will prevent mildew. In addition, polyethylene foam will protect your pipes and infrastructure from mold and thriving bacterial colonies.

What are the benefits of foam pipe insulation?

One of the main benefits of foam insulating tubes is that they can be installed relatively quickly. Tubular foam insulation slips over the pipes seamlessly, and installation times are relatively speedy. In addition, this is a very affordable solution. Foam insulation is readily available and cost-effective, making it a perfect alternative in most situations. Foam pipe insulation also comes in different sizes. This means that it is effective in different set-ups and can easily cater to most pipe sizes.

In conclusion, these are only some of foam insulation’s main benefits and perks. Anyone looking for an affordable yet effective way to prevent pipe condensation should look into this approach. Foam tubes come in all sizes and shapes and will stand the test of time.

Leave A Comment